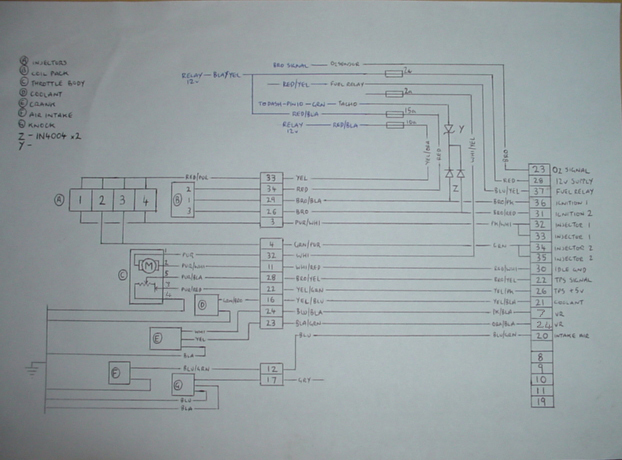

First job was to design a wiring loom for the 20valve engine. The engine I bought came with a loom so I used this as a basis for the new one - if its good enough for Vw it should work with ms. A few things were deleted from the Vw loom, for instance the coil on plug wiring (cop) as very few people had run this sucessfully at the time. I left the knock and cam position sensor wiring intact to make any future upgrades easier. The ecu plug was cut from the standard vw loom and a multi plug soldered in to pass through the bulkhead.

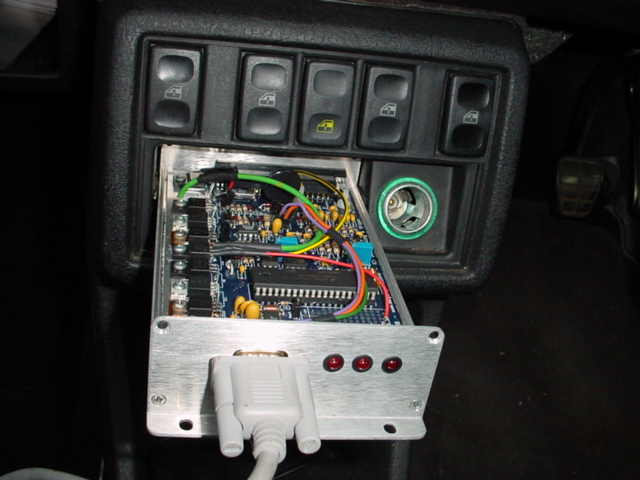

I has considered fitting the ms pcb (printed circuit board) into the original ecu case but the pin layout and its physical size made this impossible. I could not fit ms in the rain tray (normal ecu position) as it is not water tight so it had to be fitted inside the car. I spent a long time looking for a suitable bulkhead plug - it needs to be waterproof and have at least 15 pins. The ideal ones are milspec (military) but these come at a price.. I eventually found a suitable one which I took from a Vauxhall Corsa - it fits on the A pillar to supply the door wiring (I've no idea why a Corsa needs so much wiring in the doors). It has enough pins and is completely water tight. I tried to buy new pins for it but didn't find any that fitted. Eventually I located the plug manufacturer and tried to obtain a sample from them. However they would only supply a minimum of 10,000 of each male and female pins! So I used the existing pins, soldering on to the existing wires.

This got me from the engine to the bulkhead, I then made a loom from scratch to go from here to the ms which was to be fitted in the ashtray slot in the centre console. I found a couple of websites that proved useful during the loom design, a Russian site that has loads of wiring diagrams (which are thankfully in english) HERE and this guy in the Netherlands has done some good research for his Dax kitcar swap HERE.

Megasquirt & spark extra is capable of using the Bosch 60-2 crank wheel (trigger wheel). The settings can be found in the "wheel decoder settings" page. See THIS page for info and a calculator you can download. For wasted spark you need a 12v supply for the coil, pairs of cylinders (1&4, 2&3) are earthed through ms. When each pair is fired one sparkplug will be on the compression stroke & the other on the exhaust stroke (4 stroke engines). To add another coil driver transistor (VB921) use LED19 (D16 on the V3 ECU) as the extra spark output. LED17 (D14) is still used to drive the other pair of plugs. More details can be found HERE.

I had problems with the TPS sensor voltage output & used the Netherlands site for the correct wiring (which uses the earth - pin7 as the 5v supply). Also ensure you use sheilded wire for the crank (VR) sensor. The Vw loom has this as standard, the problem is this type of sensor (inc knock sensor) creates a lot of noise and can cause interference.

Follow the instructions supplied with you wideband exhaust gas sensor to connect it to ms. Do not trust a narrowband sensor on a turbo'd engine as you risk quick & severe engine damage! There is a wiring loom in the engine bay had that connects to the starter motor, alternator, coolant and oil sensors - use it for the following. To use the Golf's MFA oil temperature gauge just screw the sensor into the oil gallery and connect the green wire. You will also need to fit the high / low oil pressure sensors - use a 't' piece available from Demon Tweeks (M10x1 thread). The Mk4 has a colant pipe with 2 sensor fittings - one 2 wire and one 4 wire. For the coolant temperature gauge in the car just fit the Mk2 sensor into one of these. Use the other fitting for the ms sensor - either use the stock sensor and adapt the values with easytherm or take apart the sensor and fit a 'sperm' with the correct resistance. To run the rev counter I fitted 3 diodes from the coil wires which connect to the green wire (pin 10) of the dash gauge plug. See wiring diagram above for detail. I decided not to run the idle control or knock initially.